NANUQTM Hyperquenching Cryocooler

Get the diffraction you need by taking control of all the variables

• Eliminate ice issues

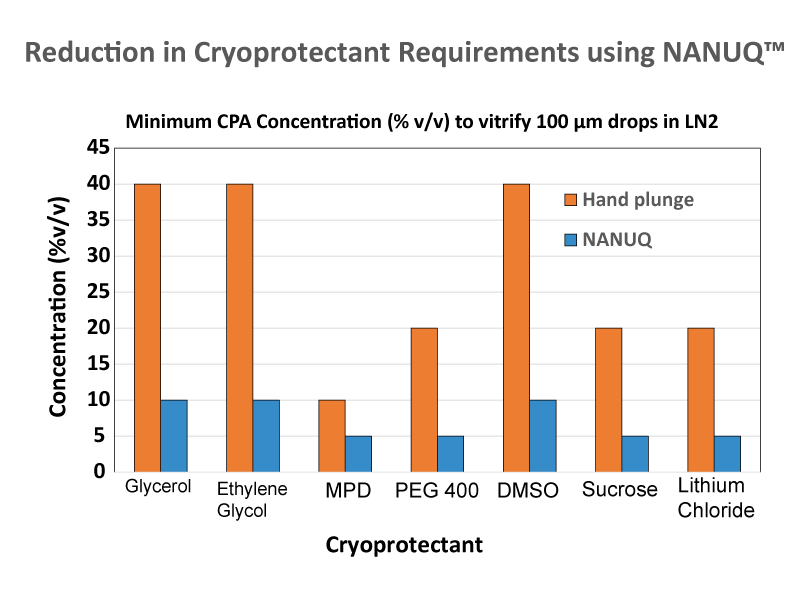

• Use less cryoprotectant

• Improve crystal diffraction

• Reduce mosaicity

• Safely place loops with auto puck filling

REQUEST A FREE INFO FLYER

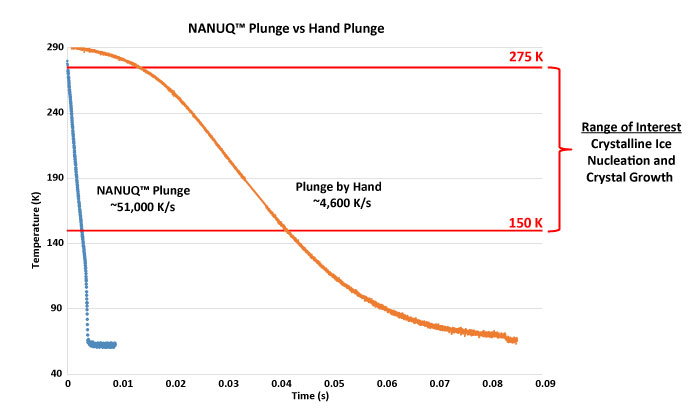

Stop plunging by hand - NANUQ™ cryocooling technology cools >50 times faster Ultra-fast cooling rates mean: • less time for the growth of ice crystals • lower cryoprotectant need • less crystal non-isomorphism • reduced cooling-induced conformation changes - in short - better data!

HOW IT WORKS:

During cryocooling, the formation of crystalline ice from solvent on and within delicate protein crystals easily damages their structure causing poor diffraction. By maximizing the cooling rate of plunge-cooled crystals, the solvent can be trapped as amorphous ice, and prevent the formation of damaging ice crystals. The NANUQ™ cryocooling technology cools samples over 10x faster than hand-plunging techniques. Faster cooling means less time for the nucleation and growth of ice crystals. In addition, lower cryoprotectant concentrations are needed to obtain ice-free samples.

(Rapid plunging and cold gas removal with NANUQ™ reduces time for ice crystals to form)

A common cryocooling technique for plunge cooling crystals is to hand-plunge them directly into an open dewar containing liquid nitrogen (LN2). With this method, crystals travel through a region of cold gas above the liquid. This cold gas is nearly the temperature of LN2. Crystals are often cooled to near LN2 temperatures, prior to even contacting the surface liquid nitrogen. The heat transfer in a gas is much slower than when the sample is in direct contact with the liquid, therefore the cooling in the cold-gas allows for significant nucleation and growth of crystalline ice on and within crystals. Using NANUQ™ technology we can remove the layer of cold gas above the LN2, maximizing the cooling rate of each sample, by going from ambient temperature directly into contact with the LN2. This ensures that heat transfer occurs within the LN2. With rapid cryocooling, water molecules are trapped as amorphous ice before crystalline ice can develop.

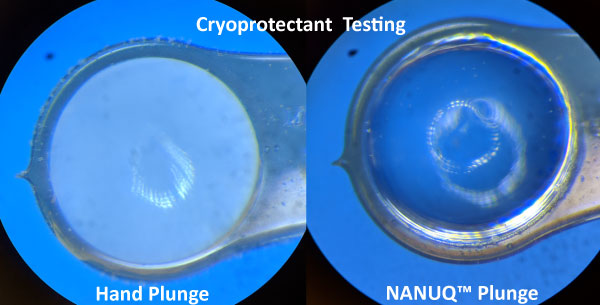

(Testing cryoprotectant concentrations easily demonstrates the impact. Cloudy droplets have ice, clear droplets do not.)

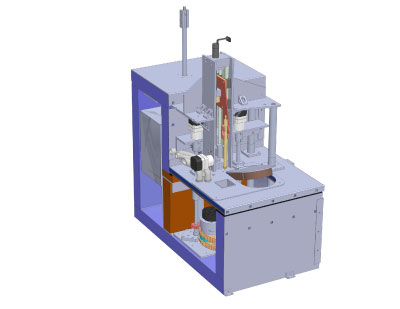

Automated ultra-fast plunge cryocooling

NANUQ's™ automated plunge mode allows for short harvest-to-plunge time, and incredibly fast cooling rates.

Automatic Puck Loading

Protect your crystals by safely loading your cryocooled samples directly into pucks with automated placement.

Efficient Liquid Nitrogen Dewar

High-efficiency insulation and a large liquid nitrogen capacity allows for hours of sample cooling without the need of refilling or worry of ice accumulation.

Patented Technology

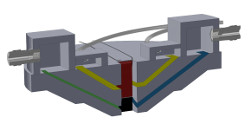

Plunge environment controls are used to define or remove cold gas layers to maintain a controlled temperature plunge path for samples. Maximizing cooling rates by avoiding unwanted cooling/ice formation that can result from cold gas above LN2.

Controlled Cooling Options

Gas-layer management and plunge speed control allows for controllable cooling rates, enabling entirely new experiments in crystallography.

Take control of every plunge:

Ultra-fast cryocooling of samples in liquid nitrogen with automatic placement into Unipucks.

Sample plunging in auto-plunge mode:

Puck carousel rotation for high precision well alignment:

Ordering & Availability Information

NANUQ™ Cryocooling Instruments are currently available for:

- purchase for your lab OR

- use at our NANUQ™ Access Facility (NAF) located in Ithaca, NY, just a few miles from CHESS beamlines

Use the form below to learn how cryocooling with NANUQ™ will improve your crystal's diffraction and enable crystallography research in a whole new way.

Patented technology.

NANUQ™ is a trademark of MiTeGen LLC.