SIMPLIFY CRYOPROTECTION & ELIMINATE ICE

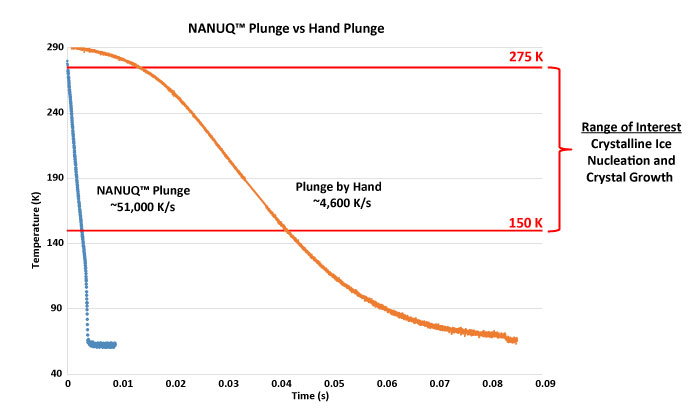

Plunging Crystals by Hand Allows Growth of Crystalline Ice

(Hand-plunged crystals see the majority of cooling done in the cold gas before contacting the liquid.)

A common cryocooling technique for plunge cooling crystals is to plunge them directly by hand into an open dewar containing liquid nitrogen (LN2). With this method, crystals travel through a region of cold gas above the liquid. This cold gas is nearly the temperature of LN2. Crystals are often cooled to near LN2 temperatures, prior to even contacting the surface of the liquid. The heat transfer in a gas is much slower than when the sample is in direct contact with the liquid, therefore the cooling in the cold gas allows time for the significant nucleation and growth of crystalline ice on and within crystals.

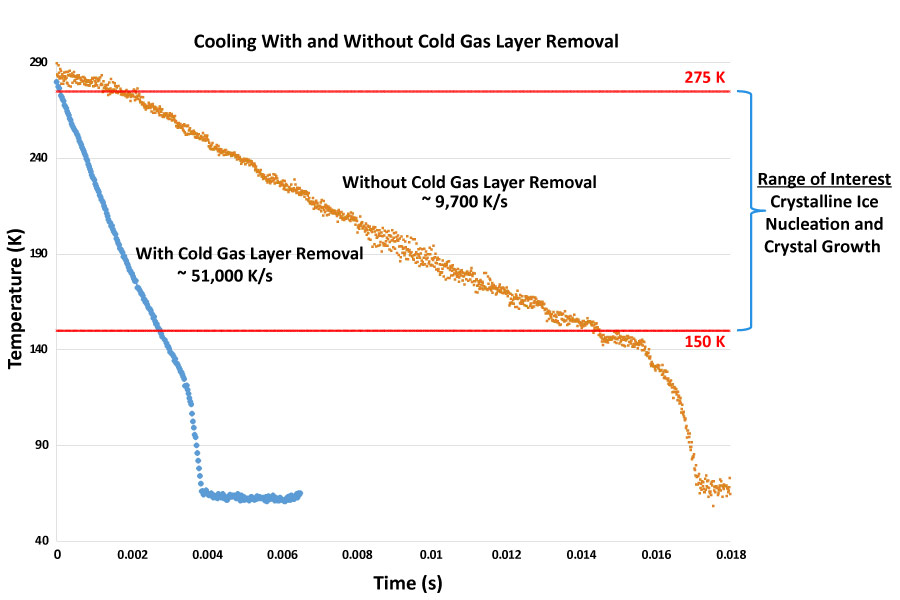

Cold Gas Layer Removal Maximizes Cooling Rates

(Automated fast plunges (2m/s) show that cold gas removal dramatically reduces the time that crystalline ice can form.)

By combining ultra-fast plunges with precisely eliminating the cold-gas layer above LN2, cooling rates for crystals can be sharply increased. The NANUQ™ cryocooling technology evacuates the cold gas above the LN2, while rapildy plunging the crystal into LN2. Samples quickly go from ambient temperature directly into contact with the LN2, without time in the cold gas layer. This method ensures that the cooling occurs within the LN2, not in the cold gas. With rapid cryocooling , water molecules are trapped as amorphous ice before crystalline ice can develop, even without the use of cryoprotectants.

After cryocooling, the samples are automatically deposited safely into Universal Pucks (Uni-pucks).

Ultra-fast Cryocooling Simplifies Cryoprotection & Eliminates Ice

Recent NANUQ™ Access Facility Users See Sharp Improvement

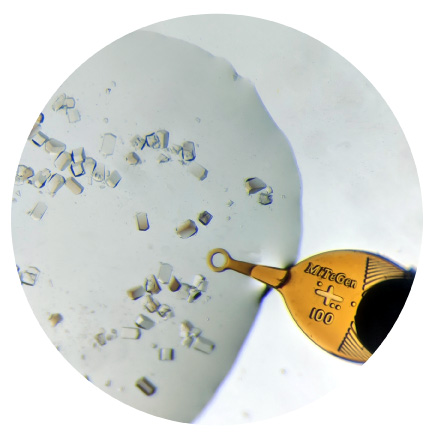

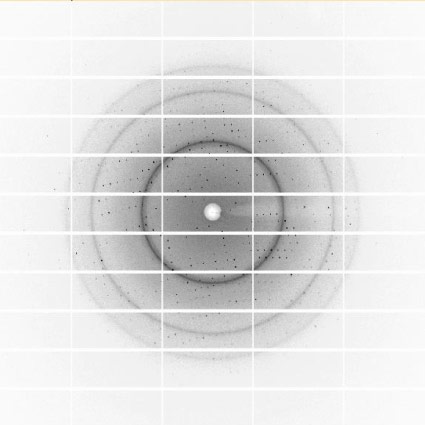

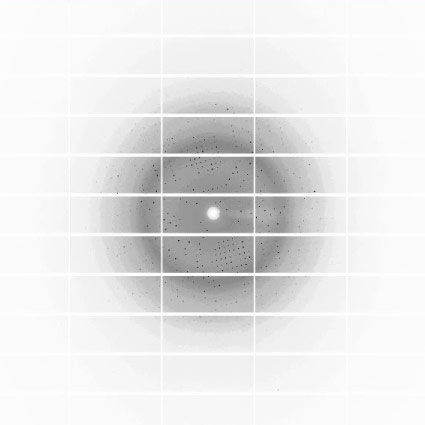

(Left: XRD of CA IX-mimic Crystal – 20% sucrose cryoprotectant – Hand Plunged into LN2 – significant crystalline ice visible) (Right: XRD of CA IX-mimic Crystal – No cryoprotectant – Cryocooled by NANUQ™ – no ice rings)

Cryocooling with the NANUQ™ proved to be superior to traditional hand plunging methods. NANUQ™ samples were prepared more consistently and were visibly free of ice, allowing the collection of higher quality data. High resolution data sets were also collected from crystals without cryoprotectant, decreasing preparation time.– Carrie Lomelino, Macromolecular Structure Group, McKenna Lab, University of Florida

MITEGEN OPENS NANUQTM ACCESS FACILITY

Users can now cryocool their crystals using the latest technology

(Users from the McKenna Lab, University of Florida, Prepare Samples for Plunge Cooling Tests at MiTeGen’s NAF) The NANUQ™ Access Facility (NAF) is located at MiTeGen’s headquarters in Ithaca, NY, USA, just a few miles away from the CHESS synchrotron beamlines. The facility and support services enable crystallographers to access state-of-the-art equipment that will optimize the cryocooling of their crystals, while reducing or eliminating the need for cryoprotectants. The laboratory facility includes a NANUQ™ cryocooling device, liquid nitrogen supplies and accessories, a Carl Zeiss Discovery V8 stereo microscope outfitted for crystallography, and all the required tools and accessories for controlled, reproducible cryocooling into the Universal V1 Pucks (Uni-pucks). MiTeGen personnel are on site to directly assist in ensuring the success of NAF users.