Get results from your crystallization plate!

February 2016

- Improve hit rates with controlled kinetics

- Safely ship crystals in the plate

- Collect XRD data without harvesting

A set of MiTeGen’s In Situ–1crystallization plates are blasting off to outer space aboard SpaceX flight CRS-8. The launch is currently scheduled for April 2016.

The plates will be used as part of a microgravity protein crystallization research project being conducted on the International Space Station.

A view of earth from the ISS. A future location for crystallization experiments with In Situ-1 crystallization plates

“We are tremendously excited to know that these plates will be going into outer space and used at the forefront of microgravity crystallization experiments. Our top design goals were to create a crystallization plate that would push the boundaries of earth-based crystallization, sample transport and data collection. To have it be chosen for use aboard the International Space Station is a testament as to how well those challenges were met.”

Benjamin Apker

Director of Business Development

MiTeGen

Ithaca, NY USA

Customer Review of MiTeGen’s In Situ-1

“In my opinion the greatest benefits were: crystal reproducibility, crystal–friendly plate transport and low background scattering.”

Dr. Ivan Campeotto MRC Centre for Molecular Bacteriology and Infection Imperial College London United Kingdom

Read the Full Spotlight

Benefits of In Situ Diffraction

“This method of data collection typically allows the experimenter to record improved diffraction data, reduces the risk of false negatives, enables a faster progression of crystallization optimization and eliminates crystal manipulation.”

“In situ macromolecular crystallography using microbeams” Acta Crystallographica Section D Biological Crystallography May 2012

X–Ray Diffraction Tip

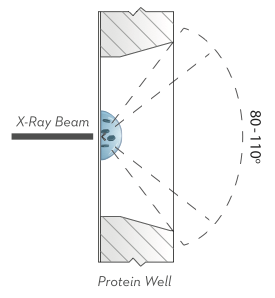

To minimize plate background and maximize your ability to detect and evaluate small crystals, use a plate with thin–film well bottom and a wide range of unobstructed incident and scattered angles. Get more tips like these: Request A Free Tips Poster!

A Selection of Crystallography Beamlines Offering In Situ X–ray Diffraction:

- Swiss Light Source (SLS)

- X06DA – PXIII

- Diamond Light Source (DLS)

- I03

- I24

- VMXi (future)

- Advanced Photon Source

- IMCA-CAT 17–ID–B (modular In Situ-1development)

- National Synchrotron Light Source II

- FMX 4–ID (2016)

- AMX 17–ID–2 (2016)

- European Synchrotron Radiation Facility

- BM14

- ID23–2

- Advanced Light Source

- 8.3.1

Beamline not listed? Contact us!

Further Reading

- “Application of In Situ Diffraction in High-Throughput Structure Determination Platforms” Pierre Aller, et al. Structural Proteomics. 2014, 1261, 233-253

- “SLS Crystallization Platform at Beamline X06DA—A Fully Automated Pipeline Enabling in Situ X-ray Diffraction Screening” R. Bingel-Erlenmeyer, et al. Crystal Growth & Design. 2011, 11 (4), 916-923