TECHNOTES

Using MicroLoops LD™

The long skinny necks on MicroLoops LD look hopelessly weak. How can they support a crystal without blowing around in the cold gas stream?

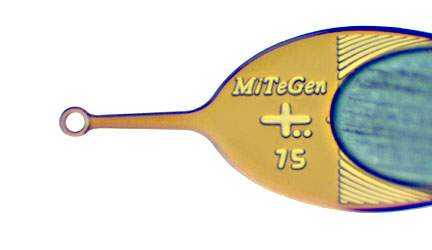

Careful design is one key. The neck and base are much thicker than the loop that holds the crystal. The base is curved like a leaf or flower petal by wrapping it around the steel rod. The overall shape was designed using finite element computer simulations and mechanical testing of scale models. All of these combine to give the most rigid skinny-neck mount possible.

A second key to minimizing sample motion is proper sample mounting. The more mass and volume you have at the tip, the more deflection you’ll get.

Consequently, it’s very important to minimize the amount of liquid surrounding the crystal. If necessary, wick away any excess using paper wicks. If you use oil to prevent the crystal from drying out, use our low viscosity LV CryoOil™, and wick or flick away any excess to get a thin coat.

Finally, make sure that the sample is in the center of the cold gas stream’s laminar flow region, and use a flow rate at the lower end of the manufacturer’s recommended range to minimize drag forces. If your lab is humid, periodically remove any ice accumulations.

MicroLoops™ LD are used in much the same way as MicroMounts™ and regular MicroLoops™. If you’re using the smaller sizes, be sure to read our tips on mounting small crystals.

Comments or suggestions? Please contact us!