Serial Crystallography

MiTeGen offers the most complete and powerful suite of tools for fixed-target serial crystallography (SX) – not just of microcrystals, but of whatever crystals your efforts yield, and not just for room temperature, but also for more efficient cryogenic temperature data collection.

Our tools help you get every crystal into the X-ray beam while maximally preserving hydration and isomorphism to maximize your overall structure determination throughput.

Showing all 9 results

-

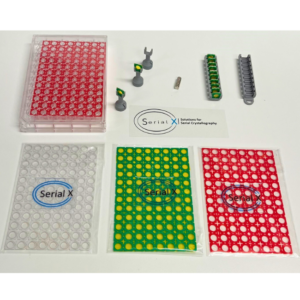

Sample Supports for Serial Crystallography

System and supports for the simple loading of microcrystals to obtain better diffraction data in serial crystallography experiments.

-

SSRL Serial MX High-Density Grid System

The high-density grid system design for efficient crystallographic data collection from multiple crystals. The system was developed for use with the SSRL robot for room temperature and cryogenic X-ray diffraction data collection.

-

Serial X Fixed-Target Chip – Serial FiX

Serial X fixed-target platform (Serial FiX) is designed for high-throughput protein crystallization, crystal... -

Serial FloXcell Serial Crystallography Sample Delivery Collection System

Serial FloXcell is a sample delivery and collection system for serial crystallography. It consists of X-ray... -

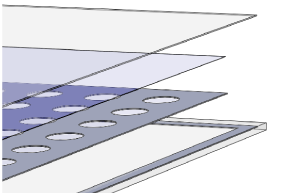

Crystallography Sample Supports System

Crystallography Sample Supports will be a next-generation crystal mounting system that changes how crystals... -

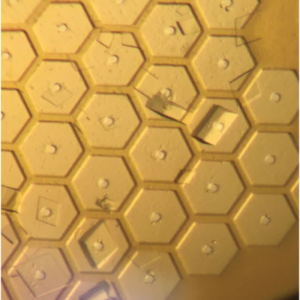

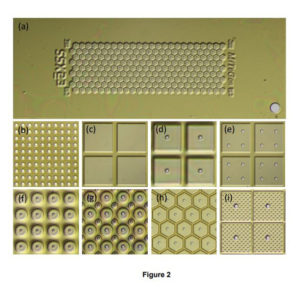

SSRL Crystallography Grids 800 Micron Holes

High-density Crystallography Grids – SSRL/SAM Compatible Design Features: Circular 800 micron diameter... -

SSRL Crystallography Grids Square Windows

High-density Crystallography Grids – SSRL/SAM Compatible Design Features: Square Windows – 1.7 x 1.9... -

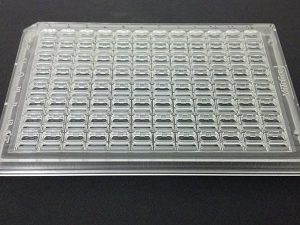

SSRL Serial MX Crystallization Storage and Shipping Plate Kit

The SSRL Crystallization Plate avoids manual manipulation of samples during crystal screening and diffraction... -

CrystalDirect Plate

The world’s lowest X-ray background crystallization plate. Ideal for in situ diffraction and serial data... -

IMISX Crystallization Plate Kit

The IMISX™ Plate is designed to perform in meso in situ serial X-ray crystallography of soluble and membrane... -

In Situ-1 Crystallization Plate

The In Situ‐1™ plate enables crystallography researchers to easily grow, transport and screen crystals of...

We offer:

Opti-SX sample supports for serial crystallography, optimized for low-background scatter, easy soaking removal of excess liquid, and rapid cryocooling, for both room and cryo-temperature data collection. Make the jump from one crystal – one loop to one drop – one Opti-SX today!

Opti-SX sample preparation workstations for loading crystals onto supports, in situ soaks, repositioning of crystals for efficient data collection, and precision removal of excess liquid, all in a near-saturating humidity environment that maximially preserves crystal isomorphism.

SSRL serial crystallography grids/supports, developed for use with the SSRL robots for room and cryogenic temperature data collection.

SSRL crystallization / shipping plate kits, which allows in situ crystallization on SSRL and MiTeGen supports and room-temperature shipping to the synchrotron or XFEL source.

Opti-SX room temperature shipping kit – an insulated box with gel packs for shipping serial supports held in SSRL shipping plates to the X-ray source.

We offer crystallization plates optimized for in situ serial X-ray data collection, including:

- CrystalDirect plates, the world’s lowest X-ray background plate

- MiTeGen’s In Situ-1 plate, which can be shipped at room temperature and held in any orientation for low-background serial X-ray data collection

- IMISX crystallization plate kit, for in meso in situ serial X-ray crystallography of soluble and membrane proteins

We also offer the Serial FloXcell serial crystallography system for delivery of a crystal-containing flow through the X-ray beam.

Why Use MiTeGen’s Serial Crystallography Tools?

Serial crystallography describes a set of approaches to collecting X-ray diffraction data from large numbers of (usually small) crystals and then assembling and analyzing data collected from multiple

crystals to determine a structure.

“Serial crystallography” in the research literature has focused on methods for delivering vast numbers of small crystals into an X-ray beam (usually generated by an XFEL). “Vast numbers” may be 10 4 to 10 10, and “small” may be 30 um to 5 um (and occasionally <1 um).

In most serial crystallography methods, crystal “hit rates” – the fraction of available crystals that see the X-ray beam – and the fraction of a given crystal’s volume that sees X-rays both tend to be very small.

Data collection is typically at room temperature where (if a non-XFEL source is used) radiation damage can be significant.

When cryogenic temperature data collection is feasible, cooling rates tend to be poor, requiring use of larger cryoprotectant concentrations and less effectively capturing your protein’s room-temperature conformation. Crystal dehydration prior to cooling can be significant, especially when small crystals are used, and this causes non-isomorphism.

These serial crystallography methods are appropriate when protein is abundant and when enormous numbers of ordered microcrystals of reasonably uniform size and shape can be readily produced.

MiTeGen’s serial crystallography tools instead focus on extending conventional high-throughput MX to make it as easy as possible to get every crystal – regardless of size – in every drop into the X-ray beam at room or cryogenic temperature while maximally preserving crystal hydration and isomorphism and minimizing X-ray background scatter for the most efficient crystallographic data collection possible.